More Efficient Fabrication Through Processes

Considering shop operations to improve your business’s profitability and more efficient fabrication.

Stone professionals have begun to examine business aspects to help streamline their shop. You may have considered setting out to consider shop operations to improve business yourself, at one time or other. Increasing your efficiency can give you a number of advantages if your fabrication shop could benefit from it. Doing this is not relegated to one specific procedure – it can be accomplished many ways.

There isn’t any one size fits all solution. Several methods are available for producing sufficient results. Just about every method has its good points and its limitations or not-so-good points. Because no method fits every situation, you should appraise the situation before making changes and get a deep understanding of your workflow. You want to know enough about how your shop operates to make wise business decisions. Here are 3 methods to consider for more efficient fabrication.

Zero in On Your Market

It doesn’t have to be just one market that you target. You could have many groups that you try to appeal to. The idea is contemplating your service or product in the perspective of an certain group of people. And then creating a work-flow for that group.

Building a work-flow that accommodates each kind of consumer can assist you with becoming more successful. This translates into better margins. Think about marketing and advertising to those specific group based on what their interests are. This post may help explain the concept:

buyerpersona.com

By using personas to communicate with your potential customer, you save work down the road because you can speak to the person in the right way and address their concerns.

Put Money into Quality Machines

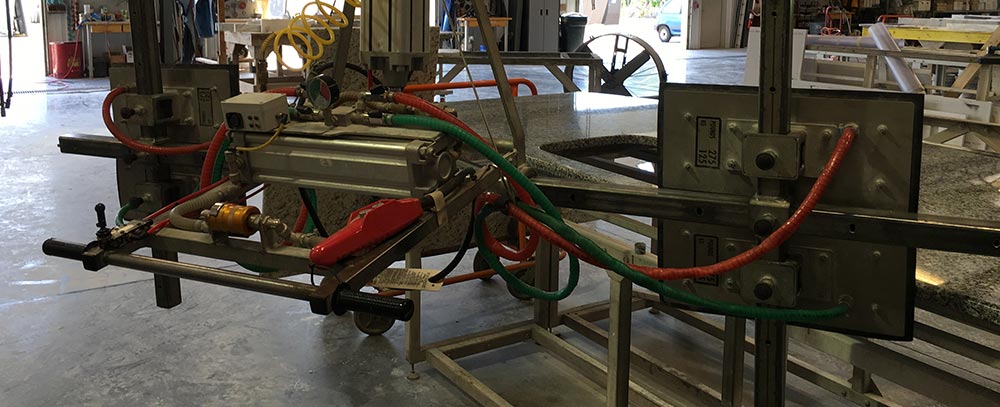

Examining and acquiring equipment to help streamline your shop can yield great results. The right bridge saw can make a world of difference in production. If it has the right cutting capacity and is good at a specific task, you may find yourself eyeing a spot in your shop for another machine that can accommodate another aspect of fabrication.

If your shop has the space and the customers and projects to support it, consider making use of a CNC machine or other specialty saw. Investing in efficient machines has the potential to bump up your productivity and your profits if your shop does enough business to support the necessary expenses that go with adding this kind of equipment.

Be Mindful of Quality

On the surface, it may sound like taking more time to produce higher quality work would be less efficient. However, the opposite is true. One area that stands out with regard to quality is installation teams. Having quality installers is a key facet of operating a successful and efficient fabrication business. What is the mark of an installer that will most likely produce high quality installs? First, they must be skilled. Second, they should have a measure of creativity. These are key qualities because there are times, as you know, that a creative solution will be necessary to get a solution that will satisfy the homeowner.

In the end, your business’s success depends on much more than the three factors that we have looked at here. However, knowing your customer, having a smooth workflow with high capacity, and a talented installation team will go a long way toward increasing your efficiency and bumping your profits upward.